Bok Saga

Dec 4 2024 - Finally we have been given keys to the blank space. First thing is to mark out the interior wall framing.

Laser and tape to square off wall locations.

December 5, 2024

Now that we have established wall layout, next step is to work with the plumbers to precisely mark out the exact locations of the plumbing and the exact concrete demolition. We need to remove chunks of the existing old concrete slab to allow us to install new drains and other features. It’s a cafe setting so this is considerably more complex than the little drain at a kitchen sink in a home. So we have to allow for drain lines from multiple appliances, from commercial ice makers, commercial coffee machines (4 of them including espresso), 3 separate sinks, commercial oven which has a steam capacity and needs water; floor drains for cleaning; Hub drains to combine multiple drains together, which all run to grease interceptors, each with two clean outs. We made a minor design change on site to locate the grease interceptors away from the main traffic area in the cafe, to a location below the movable pantry shelving. This will eliminate people having to walk or roll kitchen carts on top of the plastic grease interceptor lids all day long, but still maintain total accessibility underneath the portable pantry rack shelving. So there you go a snippet of commercial plumbing lore!

Plumbers confirming cut lines.

December 10, 2024

Plumbers were on site to begin the labour intensive process of digging out the sub-grade below the concrete to fit in all the drains. This old grade was packed gravel, super hard to punch through and so the guys used a massive jackhammer with a spoon attachment to chop away at it. Then it was hand dug with shovels. A lot of physical work still in our modern age. This is a schedule draining activity and I can see us a bit behind in our schedule plan here. I'm going to suggest an extra labour guy for them to accelerate pace, but i am not sure of their capacity. As my old mentor, a fabulous construction guy from Tennessee used to drawl, "we used to get behind schedule from time to time. Well we would just make it up, soon as possible"

Dec 12 2024

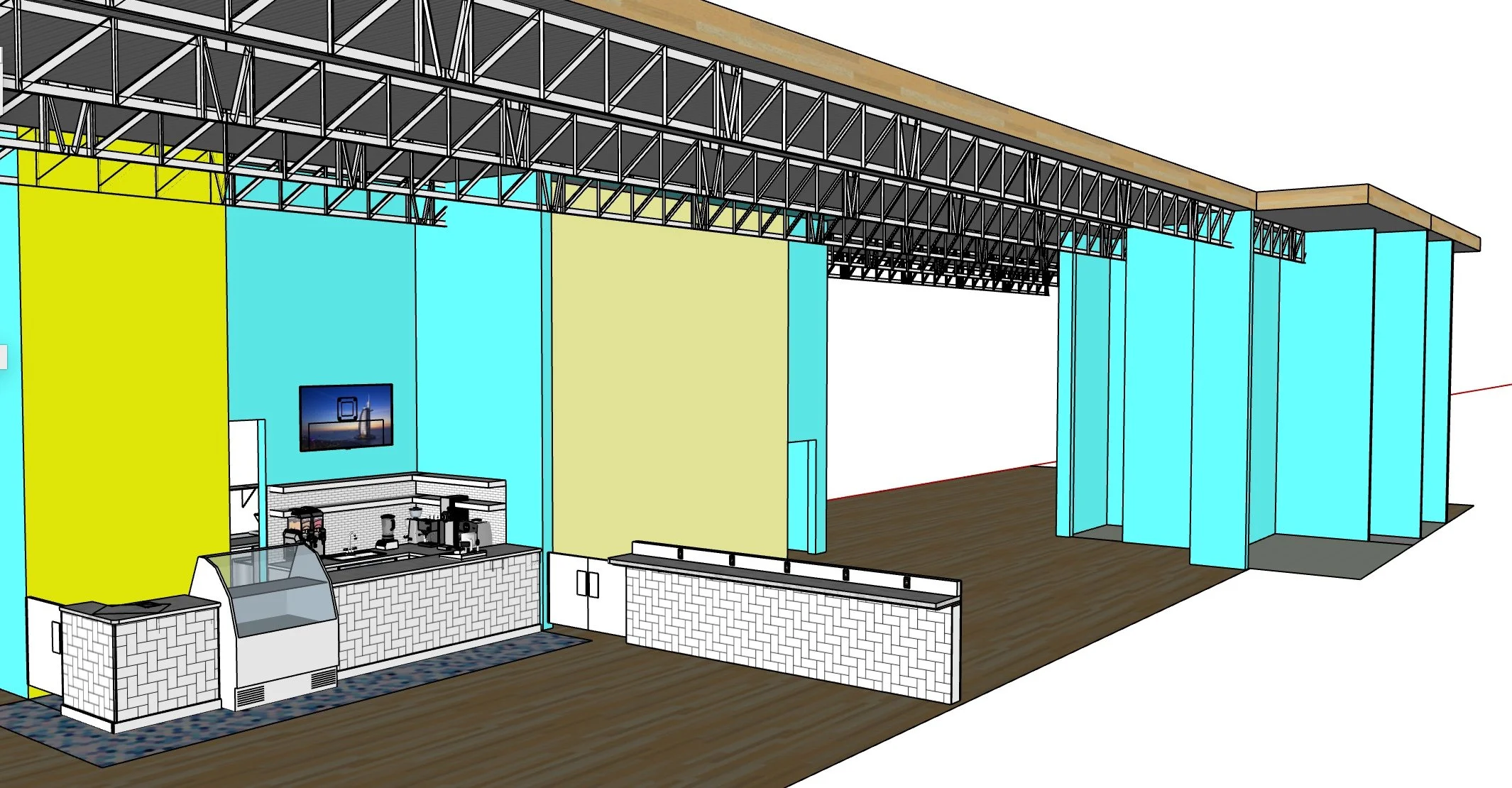

Now we are laying pipe for the underground drains. Anticipating a couple days of this and we can set for inspections. With a large number of connecting drains, we have a scheme to follow that was prepped by the architect's mechanical engineer. And ultimately, waste water has to flow by gravity to its destination- so quite a bit of effort goes in to setting heights and slopes of everything. The other key factor is connecting location to all the equipment drains. Everything from the commercial ice machine to the quad bank espresso machine has a drain that needs to be hooked up, and because the drains are poured in concrete, we kind of get one shot at locking down the locations! We also began fine tuning the lighting in the space. This is a typical warehouse environment and “features” exposed steel trusses which I quickly drew to help the clients visualize.

December 18, 2024

With ground works now complete, we await inspections. We pre-booked this because the City typically has a bit of line up, and we are hoping not to have any delays. Meanwhile we prepped all the holes for rebar, pre-cut all the rebar, and brought in beautiful washed rock to backfill the trenches with. We had a choice here; we could have backfilled the trenches with the existing road crush that had been below the slab previously. That would have been OK, but would have needed compaction. So that would involve renting a tamping machine. Its operation would be challenging because of all the new piping in the way; we would not want to damage pipes! In addition, the tamping operation has to be engineer verified on site. And lastly, because of the depth of some of our trenches, the tamping would need to be done in two steps, with two engineer visits. Well......by the time we would achieve all this, frankly, Christmas would be come and gone! Not a good option in this circumstance. By switching to washed rock, we avoid all the necessity for tamping. However, a bit of gruelling labour because all the washed rock needs to be brought in by hand, and all the road crush, brought out, by hand. This is a bit of WORK LOL.

December 19, 2024

We poured the concrete ourselves today. Overall this went smoothly. The delivery driver, a Ukrainian perhaps a little too old or choosing not to do the war, was very experienced and handled his equipment professionally. We had to contend with a frozen water line on his truck. Luckily we are doing this project at a Walmart! A hurried scope of the camping aisles yielded a super handy propane torch which made quick work of thawing the line. This allowed us to slightly tweak the mix which had come from the plant a little drier than we needed, to get to the desired 100 slump. Pouring itself was a precision operation with pinpoint wheelbarrow drops; spreading with simple wood screed, and then a lot of hand trowelling. We will be covering all of this with a tile floor, and during that process we will be able to micro manage levels if necessary but we were able to get a very flat result.

December 27, 2024

Today we began working on the fire suppression system. (overhead sprinklers). This is necessary even though the original space was previously serviced by existing sprinklers. However the code requires particular spacing along walls, and since we are adding new walls, quite a few of the existing sprinkler heads had to be adjusted or modified. To facilitate this, we arranged for the building owner to alert the sprinkler alarm controls monitor, so that they would be aware that we were affecting the system. We drained down the affected zones so that we could work on them without getting soaking wet!

December 30, 2024

Today's task is to set the plates for all the walls. This is a steel track, and we worked back and forth with the structural engineer and the supplier of the fastening system to arrive at the best solution. In the end we are choosing HILTI equipment for both the fastener and the driver system. In general, David Randolph Studio will usually select the best possible choices for gear. Goal for the day was to have all track placed and, happy to say that was achieved. Adhesive can now set up overnight. Tomorrow we will begin setting the walls and the frankly, tricky task of working around the open web trusses at the roof level.

January 4 2025

Normally, my team would have taken the week off, spent it with families and kids, celebrating Christmas. But we kept at it, pushing to stay on schedule for the clients. At first, I wasn’t sure we could do it. The space was enormous. It felt like building three two-story houses out of steel in a few days, with the clock always ticking. The challenge was in the steel itself—everything had to be screwed together, not nailed. More than 5,000 screws. Then, in some places, we had to connect our steel to huge I-beams.

By chance, I ran into the technical rep from HILTI. I was in line for a 50-pound box of screws when he struck up a conversation. He gave me advice, showed me better ways to drill, and helped us change fasteners and bits. It made a difference. We learned to slow down, save the bits, work smarter.

Back on site, we split up the work. Mark stayed up high, calculating the track sizes, handling everything overhead. Greg was at the saw, cutting metal with sparks flying, waiting for Mark’s call. I stayed on the ground, spacing the metal just right. Then Greg and I would send it up to Mark. He’d line it up, and it would be perfect.